With Easytech, Dracula Technologies aims to bring down maintenance costs on industrial wireless sensors. This Deeptech start-up created in 2011 is developing “bespoke” flexible organic photovoltaic modules. Focus with Brice Cruchon, the company’s CEO.

You turn light into energy. What are the applications?

We are developing electrical power solutions using ambient light, for electronic objects requiring micro-power levels. Dracula Technologies is more specifically targeting industrial firms which need to digitise their processes, in which they have to use sensors at various stages. Supplying these sensors using ambient light helps limit the need for cells or batteries, thus bringing down maintenance times and cutting waste!

How do you make the transition from the world of digital printing to that of the IOT?

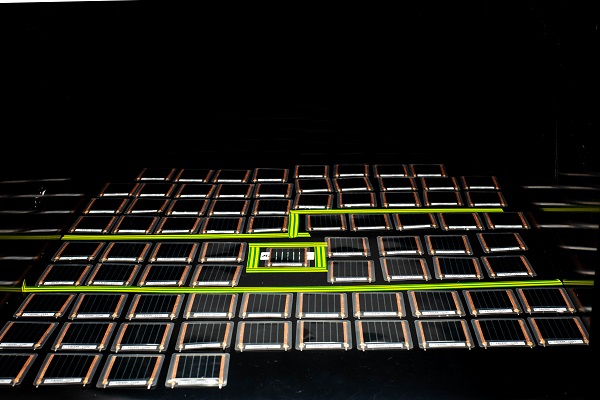

Our technology, called Layer, consists in producing OPV (Organic PhotoVoltaic) modules using inkjet digital printing techniques. We can thus create small bespoke photovoltaic modules to produce just the right amount of energy for a given application in a given light environment.

Is your approach frugal?

We use very few materials to make our modules and pay close attention to the environmental and economic impact of our processes. Our solutions are also tailored to provide just what is needed for each application and are never over-sized.

In 2022, with Grenoble-INP under the Easytech initiative, you are developing a rapid prototyping kit. What are you hoping to achieve?

Our core business is flexible photovoltaics. With Easytech, we obtained support from Grenoble-INP with development of the management electronics for our photovoltaic panels. More specifically, this time we are aiming to develop a rapid prototyping platform with reusable technological building blocks: depending on a customer’s specific needs, we will be able to propose a complete system tailored precisely to their requirements. We are working on a light sensor which will enable our Layer technology to be incorporated into a low-consumption electronic module, with the assembly being tested in the customer’s various use scenarios.

You already worked within Nanoelec/Easytech in 2014 and 2019. What did you gain from these experiences?

In the previous projects with Grenoble-INP, we were able to build up expertise and enhance our ability to develop the electronics needed to control our photovoltaic modules. We also demonstrated that by supplying an RFID tag with our small flexible photovoltaic sensors, we could increase the detection range by a factor of 4. We raised 2.4 million euros in 2019 to launch pre-industrialisation of our module for this particular application. The performance gains are attracting the RFID tag manufacturers, with whom we are currently negotiating on various large applications markets.

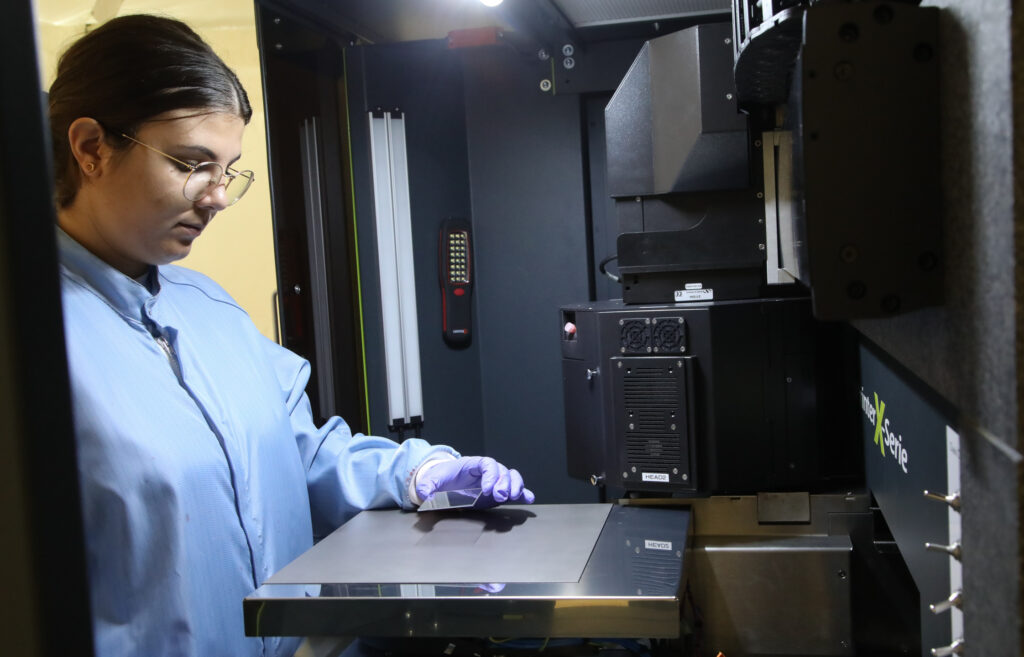

OPV Technician at Dracula Technologies printing organic photovoltaic modules on an industrial machine (c) Dracula Technologies

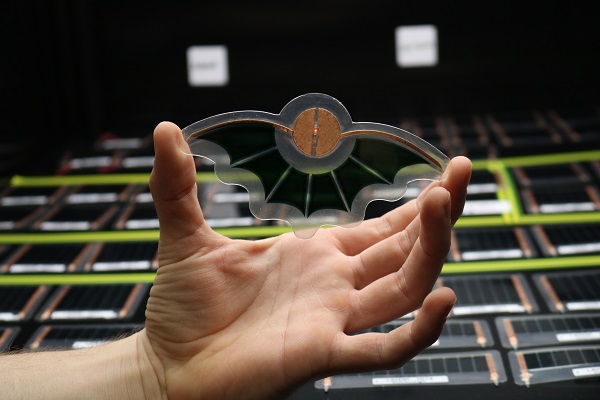

Dracula Technologies develops “bespoke” flexible organic photovoltaic modules (c) Dracula Technologies