IROC Technologies joins the IRT Nanoelec consortium on 1 september 2021. The company is a spin-off from the Tima laboratory (CNRS, Grenoble-INP &UGA) and is developing a range of services for reliability in the microelectronics industry. Dan Alexandrescu, CEO of IROC Technologies, explains the challenges in this field, the iroc approach and the shape of its collaboration in Nanoelec.

Why is reliability a key parameter when developing components?

Defense and space have always needed special electronic components to carry out missions in harsh environments: radiation testing is in fact part of the military and space certification process. However, the constraints arising from the increasingly widespread use of components, for example in the aeronautics and automotive sectors, are increasingly strict if the dependability goals are to be met for critical equipment.

To counter these vulnerabilities, IROC Technologies is providing the circuit designers with analysis software, services and expertise to improve the quality and reliability of components. What is your approach?

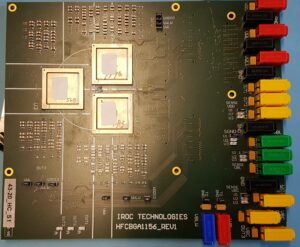

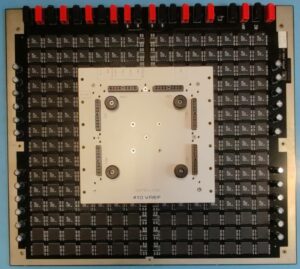

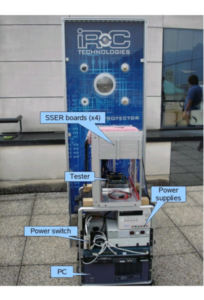

Iroc offers its customers a range of solutions for characterizing and verifying the level of reliability of electronic components before they are placed on the market. Accelerated test activities for electronic components account for 60% of the company’s business. With regard to terrestrial and aeronautical applications, in order to obtain satisfactory predictions concerning the behavior of an electronic circuit, we are working together with laboratories which can provide a spectrum of neutrons similar to the atmospheric spectrum.

At Nanoelec, you intend to work more specifically on “single event effects”? What are they?

Single Event Effects (SEE) come from the interaction between an energetic particle and a microelectronic circuit. Ionizing particles or radiation can tear off or excite the electrons of the atoms of the material through which they pass. This disturbance can unexpectedly modify the operation of an electronic circuit. We aim to take part in expanding the expertise of the Nanoelec/Characterization program on the effects of irradiation, in particular if electronic components are affected by these SEEs.

The idea is to innovate by boosting R&D in this field. The aim is to improve the experimental resources and their performance and to develop analytical methods to predict the behavior of a circuit subjected to a neutronic environment, along with simulation tools.

You are aiming in particular to “qualify” Nanoelec’s irradiation resources for the needs of your customers?

We are preparing to qualify a selection of representative electronic circuits – static (SRAM) and dynamic (DRAM) memories, reconfigurable devices (FPGA) based on SRAM or FLASH, analogue devices, etc. – for the operating environment. The results obtained will be corroborated by an in-depth analysis using prediction tools and nuclear databases developed by the company.

On the basis of the observations obtained with these tests, we will then propose prediction and simulation methods and tools. We will do this in collaboration with the other Nanoelec partners, because the Carac program brings together the key players in the value chain: the institutes operating large international instruments in Grenoble (ESRF, ILL), academic laboratories (CEA, CNRS) and industry (Schneider Electric, Soitec, STMicroelectronics).