Back with Pascal Metzger, president of SET on the development of NEO HB, the company’s latest production equipment developed in partnership with Nanoelec and presented at Semicon Taiwan last year. The machine allows chip to plate assemblies by hybrid / direct bonding. The main technical characteristics are high precision after assembly, a high rate, several hundred chips per hour, and a very low level of particulate contamination, compatible with direct bonding. These characteristics make it possible to address production markets where the interconnection pitches are very small, less than 10 μm. Applications such as high performance computing or memory stacking can be performed on NEO HB.

“Being in a consortium within Nanoelec allows us, from the R&D phase, to adapt the design if necessary and to qualify our machines by having access to real components and to the production issues of manufacturers. The work and the exchanges within the IRT bring us a vision of end user on our machines “, explains Pascal Metzger, president of SET.

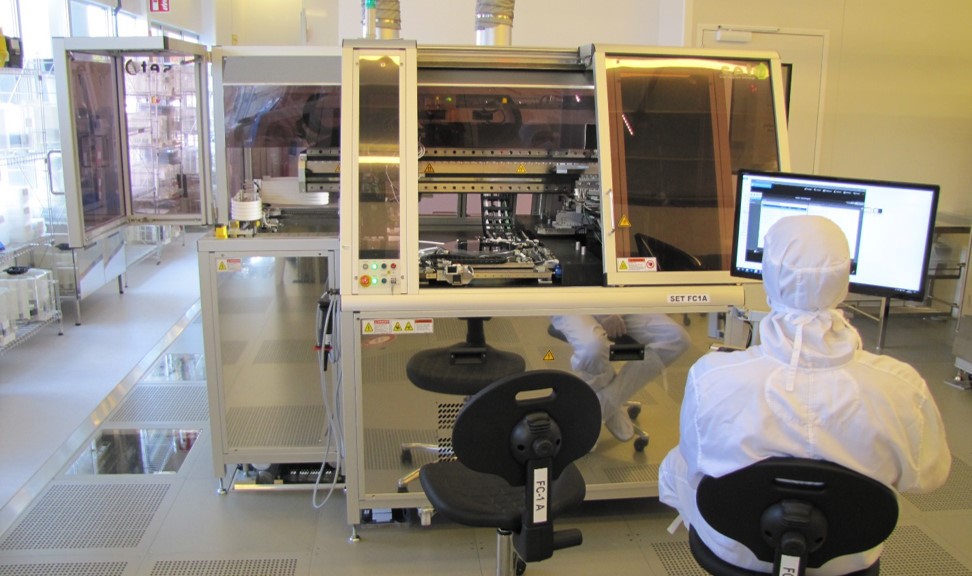

The installation, from 2017, of a SET prototype of a direct bonding machine in CEA-Leti clean rooms, and its progressive qualification led to several publications in major conferences in the field, which increased SET’s visibility. “In fact, the opportunities to publish scientific articles with academic teams strengthen our credibility and our visibility in the necessarily very narrow and very demanding equipment market for microelectronics”, continues Pascal Metzger.

The Haut-Savoyard company, born in 1975, has the specificity of being a SCOP since 2012, following its takeover by its employees. With more than 350 machines installed in clean rooms around the world, it is a recognized leader in the market for high-precision flip-chip bonders.

“Nanoelec represents a very stimulating multicultural opening for us,” notes Pascal Metzger, who also underlines that the IRT system has greatly contributed to the realization of the SET production machine project.

“We are continuing the collaboration within Nanoelec, to characterize the potential markets for NEO HB – in particular the manufacture of electronic components for memories and intensive computing – but also to strengthen our positioning on the more general market of the precision assembly ”, adds the president of SET.